Are you left- or right-brained? Right-brain skills are finding an increasing role in improving supply chain management.

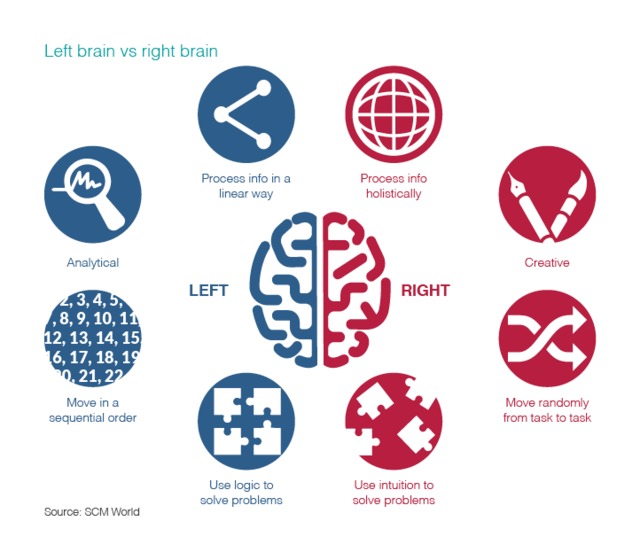

If asked, the majority of people would classify working in supply chain as a job for left-brain rather than right-brain individuals. But things are changing. Our concept of the difference between these two sides of the brain is based largely on the work of Nobel Prize-winning scientist Roger Sperry in the 1960s: The left side of the brain takes care of analytical tasks, while the right deals with emotional and interpretive responses.

It was always the presumption that supply chain experts have more left-brain leanings, falling into the logical, analytical side of things. It well-supported the traditional supply chain world of automated manufacturing, conveyor belts and highly synchronized distribution networks. A job in this sector didn’t need any of those soft creative, interpretive and emotional skills we came to expect in other sectors.

Technology Changed the Game

But the fact is, advances in technology are shaking up the status quo. Those left-brain tasks that used to sit firmly in the realm of the everyday worker are being subsumed by the latest tech innovation. For example, the complex statistical calculations about supply and demand, the physical sorting of materials and so many of those conveyor belt tasks are now completed by robots and computers. In fact, in an SCM World survey, 35 percent of supply chain executives said that automation and robots were both disruptive and important, providing opportunities to improve agility and cut production costs. What’s more, an even larger proportion of respondents said the same of digital networks (66 percent), and analytics and modelling (77 percent).

We only need to look at Google’s recent DeepMind artificial intelligence win at a historic Go contest to see that the abilities of robotics are only continuing to grow and improve. It seems that computers really are getting smarter, and our brains can no longer compete with technology when it comes to logic and analytics.

What does this mean for us humans working in supply chain?

I believe that the outlook is bright. Instead of an army of left-brainers employed to carry out mechanical, logical and purely analytical tasks, we are going to need a supply chain workforce able to do all the things that computers can’t. We’re going to need people who can draw conclusions from these complex systems and put them in context. And even more importantly, organizations are going to require people with strong communication skills who can work within and between teams across the multi-various and interconnected parts of the supply chain. In short, people with right-brain skills.

The Link between Supply Chains and Right Brains

Right-brain work is holistic, intuitive and creative. Right-brain thinkers excel in storytelling, complex design and understanding the bigger picture. A key right-brain activity is to process information holistically. People in supply chain do this all day, every day. They are network thinkers, must understand intangible value, and most notably, must process information from across the entire chain of functions and businesses.

Take production planning, a traditional left-brain activity. Working with interconnected robots that can be reprogrammed in minutes, sequencing simulations that digitally test thousands of work paths in seconds and using Internet of Things (IoT)-enabled machinery to ensure precision, the production planner of the future becomes a master craftsman. Freed from the need to manufacture long runs for low unit costs, this job becomes one that allows businesses to deliver products in batches of one, without compromising profitability. Infinite SKUs, infinite variety.

In a similar vein, we could see logistics managers taking responsibility for customer satisfaction. Analytics and automation in fulfillment centers can deepen the range of options available to build a load, plan a route and confirm the customer’s readiness to receive shipment. Extending this further back up the supply chain to include late-stage personalized packaging and forwards to a wider range of delivery options, such as delivery robots and drones, plain old logistics could become the sexiest job in the supply chain.

The Future of Supply Chain

Right-braining the supply chain can usher in a new wealth of expertise. The importance of the sector is growing not simply in business terms, but also in its ability to combat poverty in the further reaches of the manufacturing chain and develop methods of production that are sustainable across the globe. Solving problems on this scale involves creative thinking and imagination, as well as pure analytics. The future of our profession is not just for the engineers and technicians, but for the designers and storytellers as well.

Source: Supply & Demand Chain Executive